|

|

|

Project #4 - Getting the best from your Fox .40

|

Specifications for Fox .40

Bore: .840

Stroke: .715

Disp: .396

Weight: 9.5oz

RPM: 12,800 w 10-6

ABC, BB and Bushing models all have same specs

|

|

User Manual for engines with MKX carburetor

User Manual for engines with EZ carburetor

Evolution History of the C-Frame .40

Introduced in the mid-80's, this "C-frame" series engine has its origins the .36 combat

U-control engine. The .36 crankcase was modified to accept a

muffler, and lengthened to allow the installation of a carburetor.

With the addition of a new carburetor designed to fit the unusual

square intake stack, the compact C-frame series was born.

Original "Compact Series"

engines were introduced with a single rear main ball bearing.

The front of the crankshaft ran directly in the aluminum casting.

Durability problems quickly became evident with this configuration

and a ball bearing was soon added to the front as well. (The

current .40 sport bushing version incorporates a sturdy bronze

bushing and has no such durability problems.)

Engines in this series originally

included the compact .29, .36, and .40 bushing series, as well

as the .40BB standard and .40BB Deluxe. Bushing and standard

BB models all use steel liners and mehanite pistons, while the

deluxe version employs ABC technology. The .29 and .36 sizes

are no longer produced, but during their relatively short production

period exhibited few running problems. The .40 size engines in

this series continue to be produced and we will address some

problems that have occurred with these. Test reports on early

models praised the high power, excellent idle and friendly running

qualities of this engine series (.40 size) and our experience

confirms this. Some later examples, however, proved to be much

less user friendly.

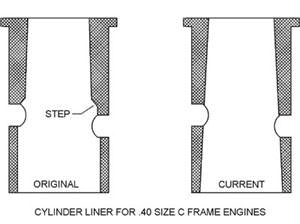

Although they have remained virtually

unchanged in external appearance, over the years internal changes

have been made which significantly affected performance and handling

qualities. The single greatest change involved the design of

the cylinder liner. Very early examples, including ABC types,

employed cylinders that were not continuously tapered as you

might expect in a non-ringed design, rather they were abruptly

"stepped" down .002" in diameter just above the

exhaust port. Only the upper portion of the cylinder was slightly

tapered. Later models employed cylinder liners with a more conventional

constant taper. The diagram below is exaggerated to better illustrate

this:

|

Since the fit was critical, and

the original stepped ABC liner proved difficult to hone after

being chrome plated, pistons were individually precision ground

to fit each liner. Obviously, it was difficult to keep production

costs down with this approach. The conventional configuration,

however, apparently allowed more latitude in fit. Now with minimal

liner honing, and only a few standard piston sizes, a good fit

was quickly achieved. Those models employing steel liners were

likely also changed to keep production procedures consistent,

but it seems only Duke really knew for sure. Unfortunately, this

change also negatively affected performance and running qualities.

(Particularly the ABC version). Needle valves became more difficult

to adjust, and engines were prone to quitting, particularly when

operating in the midrange. Intolerance to nitro was another symptom,

and anything over 5% often aggravated the problem. Maximum rpm

was also reduced noticeably. Older versions, including bushing

models, often turned a 10X6 propeller at 14,000 rpm, while many

later examples ran closer to 13,000 rpm. (In fairness, it should

be noted that Fox only ever claimed 13,000 for these engines,

which is still very good performance.)

Perhaps the most significant

of these problems was the tendency to quit when operating in

the lower mid-range. After only a few minutes running at about

half throttle or less, the engine would quit when the throttle

was advanced, and no amount of adjusting could eliminate this.

Since the original MKX carburetor was slightly rich in the midrange,

it allowed the crankcase to slowly load up with fuel. When the

throttle was advanced, the excess fuel simply put out the plug.

Unlike earlier versions, these engines had become quite sensitive

to the fuel mixture, and would quit rather than clear. While

the introduction of the EZ series carburetor offered some relief,

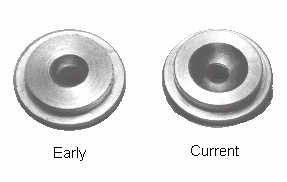

the problem was not entirely solved. Lowering the compression

provided further improvement and this was achieved with a new

head button design. The following picture illustrates the difference

between early and current model head buttons. |

|

|

The combination of the head button

modification, a modified piston and some fine tuning of the liner

taper, have substantially restored the running qualities displayed

by early versions. Previous carburetor woes can also be overcome

with the new "improved" two-needle design, however,

for some strange reason, Fox continues to supply the .40 with

the troublesome EZ series carb. The new two-needle carburetor

is available from Fox at the same price as the EZ series. Power

still lags slightly behind early models, but is still very good,

particularly when you consider the compact size and light weight

of this engine series. Even the economical bushing version easily

out-powers most imports of similar size and configuration

Some Solutions:

If you own one of the friendly early versions, and it is still

in good condition, treat it well and be sure to use fuel that

contains some castor oil. The original cylinder liner and piston

set are no longer available, so a rebuild will involve a new

series liner, piston and a new head button. One of the new improved

TN carburetors is also highly recommended. Ball bearing equipped

engines containing the original stepped liner can be identified

by the front of the crankshaft. On early versions the crankshaft

had eight small studs, and the thrust washer was keyed to fit

these. Later versions employ a taper locked thrust washer and

the crankshaft has no studs. Bushing engines, however, continue

to use the crankshaft with the studs so cannot be identified

in the same way.

If you own an "unfriendly"

engine that was built during the troublesome design transition

period, there are a number of possible options that provide a

solution, depending upon the cost and/or level of performance

you consider acceptable.

OPTION 1:

Our first recommendation is to upgrade

to the latest standards. Assuming the piston-liner fit is still

good, this is easily accomplished by just installing a new head

button and one of Fox's new improved

TN carburetors. This new carburetor (part # 2600) replaces

both the MKX and EZ series, and works very well.

OPTION 2:

If you are not overly concerned with

the somewhat rich midrange exhibited by some two needle MKX carburetors,

you may find that just installing the latest head button is an

acceptable second best option. Needle settings will be more friendly

and, while the engine may still stumble a little in the midrange,

it should no longer quit when the throttle is advanced.

If you like to experiment, an

MKX carburetor with an excessively rich midrange can be improved

somewhat by slightly enlarging the jet in the spray bar. Remove

the jet assembly from the carburetor, remove the high-speed needle,

then drill out the spray bar with a #55 drill.

NOTE: This modification is

for older .40 size "MKX" series carburetors only. Don't

try this on the new "improved" two-needle carburetor!

|

|

This modification allows the

idle mixture needle to be screwed farther into the jet to lean

the midrange without causing an overly lean idle. Because it

will now travel further into the jet, in some cases it is necessary

to shorten the idle mixture needle slightly to prevent it from

contacting the high-speed needle when the throttle barrel is

fully closed. This is accomplished by filing a small amount off

the tip.

OPTION 3:

The simplest, and least expensive solution

involves simply adding two .01" shims between the head button

and the top of the cylinder liner to reduce the compression.

While not as effective as the first two options, it may still

be acceptable, particularly if the nitro content in your fuel

does not exceed 10%. You can also apply the spray bar modification

shown in option 2 to further improve midrange performance, if

required. While not as effective as the first two options, it

may still be acceptable, particularly if the nitro content in

your fuel does not exceed 10%. You can also apply the spray bar

modification described in option 2 to further improve midrange

performance, if required. |

NOTE:

Many engines (particularly the ABC version)

were prematurely "cooked" as their owners tried in

vain to overcome the rich midrange, and flameout problem, by

setting the high-speed needle overly lean. Some earlier ABC engines

were also not fit properly. Before applying any of the suggested

improvement options check the piston-liner fit! (Project #6 Determining Engine Condition describes

how to check this). |

|

Carburetor Air Leak:

When first introduced,

the unusual square-neck carburetor was retained with a single

setscrew and sealed to the crankcase with RTV silicone. On later

engines a rubber gasket is used along with two setscrews. The

RTV method was a better method for sealing these carburetors.

The fit of the carburetor in the crankcase casting is often such

that tightening the setscrew/s tends to push the base of the

carburetor away from the crankcase. The very thin rubber gasket

provided may not seal properly. We have even encountered situations

where the carburetor will jam in the crankcase before it fully

seats against the gasket. The fit is quite variable! We recommend

deleting the gasket and applying silicone as done previously.

If the carburetor is not completely sealed to the crankcase,

the engine will run very poorly!

|

|

Some recent problems:

There have been new problems

showing up in more recent engines. These are related to a combination

of the EZ carburetor and a modification to the crankcase. The

crankcase has been modified internally to include a thin slot

that runs between the carb. intake and front bearing. The intent

was for the intake vacuum to prevent fuel from leaking past the

front bearing while the engine is running. Unfortunately, in

many cases, too much air is also drawn in through the slot upsetting

the mixture. (This is basically an air leak!). The air-bleed

EZ series carburetor often does not have the adjustment range

to compensate for this, resulting in the inability to achieve

a proper mixture adjustment.The engine may run poorly in the

low to mid-throttle range. Some engines suck in enough air that

they run poorly over the entire throttle range. The engine must

be disassembled to check for the presence of the slot. With the

crankshaft removed, look through the rear cover toward the front

bearing. You should be able to see the slot between the carb

intake hole and front bearing. We have been filling the slot

with JB weld to fix the air leak problem, but this must be done

carefully so that the operation of the crankshaft is not impeded.

Remove the front bearing and clean the crankcase thoroughly with

solvent. Carefully fill the slot (using a toothpick, etc.) trying

not to get too much excess. Allow the JB weld to set for a while,

but not fully cure, then insert the crankshaft. The front edge

of the crankshaft will neatly scrape away the excess JB weld

for a perfect fit. Allow the JB weld to cure fully before installing

the front bearing and re-assembling the engine.

Other Suggestions:

We recommend you read the page on EZ series

carburetors , if your engine is so equipped. There have been

some problems with these, apart from the slot/air-leak problem

described above. |

|