|

|

|

MESSAGE FROM DUKE FOX: We are very proud of this series of motors and want yours to give you the best possible service. Please read this manual in its entirety and follow its instructions to the best of your ability. If you have any questions not covered here, please feel free to call us at Area Code (501) 646-1656 SUITABLE MODELS: These motors are intended for sport and scale type model airplanes that their size and weight would fit. |

|

WARNING: There is always the possibility you may lose control of your model. Do not fly in any location where your model might strike people or do property damage should this occur. |

|

INSTALLATION: Your Fox motor mounts in the normal manner. If your airplane calls for a firewall mount, we recommend the Fox #50403 one piece metal mount, as it is very rigid. If your airplane is designed with a hardwood beam type mount, be sure they are well braced between the two beams, and the beams are gusseted to the firewall, and, preferably, to one another. Flimsy motor mounts will allow the engine to vibrate excessively and may damage the model and cause foaming of the fuel tank. Also, excessive vibration can cause glow plug failure. If a cowling is used, provisions should be made for both air inlet and outlet. PROPELLERS TO USE: We recommend you always use a hardwood propeller of the size shown:

We urge that you do not use nylon propellers because their flexible nature causes more vibration. Also, if you should accidentally get hit by one, you will be hurt worse than if hit with a wooden propeller. |

|

WARNING: Always keep clear of the propeller. It is possible for a propeller to cut off a finger or for a piece to come off and put an eye out. |

|

FUEL TO USE: Model airplane fuels are a mixture of methanol, oil, and various additives to improve ignition, add power, and cut down carbon deposits. It is important to use only fuel with a castor oil lubricant, otherwise, your engine life will be drastically reduced. Nitro is another fuel ingredient that is often used. Its function is to "advance the spark". To determine if you need any, or more nitro, start your engine, open the throttle wide open and set your high speed needle for maximum power, then back it out slightly. Do all this with your booster battery connected. Now remove your booster leads - if your motor slows down, more nitro is indicated. Fox Gold Star (5% nitro) and Duke's Fuel (10% nitro) have castor oil lubrication and should work satisfactorily. |

|

WARNING: Model airplane fuel is both flammable and extremely poisonous. Use the same safety precautions you would use with a can of gasoline or a bottle of poison. |

|

GLOW PLUGS This series motors all use the long thread glow plug. We recommend standard type for control line motors, and our RC or 4 cycle plug for RC use. The 4 cycle plug costs a bit more but does give a more reliable idle. TO START YOUR MOTOR: 1. Mount your motor securely on a mount that does not put a strain on the mounting lug. #4-40 screws are the size to use. The fuel supply should be so positioned that the fuel level is no more than 1/2" above or below the fuel nipple. The fuel line should not be higher than the fuel level at any point. Use Fox medium size fuel line. In case the factory needle settings have been disturbed, re-set following steps 2, 3 and 4. 2. Close the throttle - adjust the idle stop screw (the one on top), so you can see a hairline opening in the intake when the throttle is pushed closed. 3. Holding the throttle shut, screw the low speed needle (one on the exhaust side) in until it is snug, then back out one full turn. 4. Screw the high speed needle in until is seats, then back out four full turns. 5. Set the throttle at 1/3 open throttle position, connect the glow plug wire and crank counter clockwise with a quick, snappy, flipping motion. If it does not start in a few flips, try choking it a turn or two. It should start and run at these settings. |

|

WARNING: A model airplane motor can get hot enough to cause a serious burn. Do not touch the motor right after it has been running. |

|

BREAK IN: Your Fox motor has a closely fit piston which requires from 15 to 30 minutes running before it will idle reliably. No special fuel or propeller is necessary, however, take care that the motor is not run overlean (leaned in to the point that is loses power). |

|

WARNING: Never fly a control line model within 200 feet of power lines. Death by electrocution is possible if your model comes near a power line. Direct contact is not necessary. |

|

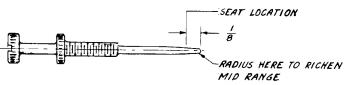

FINE TUNING YOUR FOX SERIES 6 CARBURETOR The 36RC and Compact 40RC all use the same carburetor. The most reliable settings are those in which the lower half of the throttle range is as lean as possible without stalling, becoming slightly rich in the 3/4 to full throttle setting. The adjusting screw on the exhaust side is the low speed needle. The adjusting screw opposite the exhaust is the high speed needle, Both needles screw in to lean and out to richen. The adjusting screw on top of the carburetor limits how far the throttle will go closed and is used to control the idle speed. The carburetor assembly is held is place with a set screw and gasketed with silicone rubber compound. Both the high speed needle and low speed needle purposely have loose threads to allow the needle to have a little "float" to find its seat. No carburetor can work perfectly for all propeller sizes, altitudes, fuel viscosities and tank locations. If after your motor has been broken in you do not like the way your carburetor performs, you can tailor it to your liking by working on the low speed needle. If you goof, you have not ruined an expensive part. |

|

If the motor will not get rich enough at high speed:

If the motor is lean at midrange:

If the mid-range can be made to work fine by screwing the needle in a bit too much for a good idle:

If you mess up you have not ruined an expensive part. Take time to get it working just exactly the way you want. WHEN THINGS DON'T GO SO WELL: Motor Won't Start

Motor Won't Keep Running With Glow Plug Heater Removed

Motor Goes Lean and Quits after a Couple Minutes Running

Glow Plug Burns Out Every Flight

IN CASE OF CRASH, DO NOT TURN THE PROP OVER YET

OTHERWISE, PROCEED TO DISASSEMBLE Inspect all parts - discard any that appear damaged or worn. New parts can be obtained directly from the factory by calling (501) 646-1656 during business hours. If repairs are more than you want to handle and you desire us to rebuild it for you, mail directly to us. We will disassemble the motor, replace all necessary parts, test run and return the motor to you charges collect. It has not proven practical to make any sort of estimates. We will assure you, however, that our charges will never be more than 60 percent of the list price of a new motor. |

GOOD LUCK, AND ENJOY YOUR FOX MOTOR -

IT IS ONE OF THE FINEST BUILT ANYWHERE.