|

|

|

Project #8 - Taming the 1.20 Twin

|

User Manual User Manual

Utilizing cylinder assemblies

from the Eagle II .60, the 1.20 twin was introduced in the late

70's with production continuing into the early 80's. Early models

were equipped with the ancient 2-jet carburetor while those produced

from 1980 and on used the newer MKX series carbs. These engines

were known to be finicky to adjust and run hot, with a tendency

for a cylinder to flameout during throttle transitions. This

should not be too surprising since the Eagle II .60, upon which

the 1.20 is based, exhibited the same problems, so with the 1.20

the problems are double! Fortunately, the 1.20 responds just

as well to the same modifications that we have used to tame the

.60. |

So, what's the problem?

The Eagle .60 II was

produced at the beginning of an era during which Duke was obsessed

with making his engines perform well on FAI (no nitro) fuel.

This resulted in unusual head button designs with very small

combustion chambers, wide squish bands, and high compression.

While Duke did manage to get good power from his engines on FAI

fuel, this often came at the expense of poor running qualities

when using the typical 10-15% nitro fuel that most modelers preferred

to use. Engines were finicky to adjust, ran hot, and would often

flameout during throttle transitions. So, naturally, the 1.20,

being two Eagle .60's, exhibited the same problems. Having two

two carburetors to setup, particularly the older 2-jet types,

certainly didn't make running the 1.20 any easier either.

|

|

The Fix

The first

step is to obtain the parts you will need. An absolute must is

to order two new Eagle IV series head buttons, along with four

0.01" shims from Fox Mfg. Don't even bother messing with

the engine without these! If your engine has the earlier

2-jet type carburetors, upgrading these to the MKX series, NOT

the EZ series, is highly recommended. The ancient 2-jet

carb. is difficult enough to operate when there is only one to

worry about.

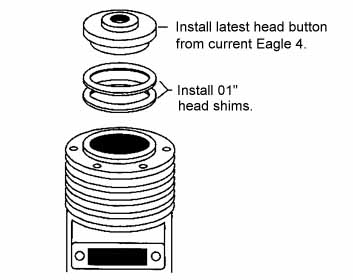

Install the head

head buttons and shims as shown in the diagram below: |

Installing Head Button

and Shims

|

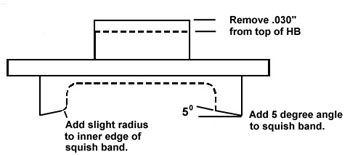

While the basic

head button fix is generally acceptable, if you have the capability

to do a bit of simple machining, the Eagle IV head button can

be improved further. By lowering the position of the glow plug

by .030" and adding a 5 degree angle, and a slight radius,

to the squish band, you can achieve an even smoother running

engine. The diagram below shows the details. The squish band

angle is not ultra-critical, and the radius can be easily achieved

by wrapping some #400 sandpaper around a small dowel, and working

the inner edge while spinning it up in a lathe. Don't get too

carried away, just round off the sharp edge a bit. Again, not

really critical. The shims mentioned above are still required. |

Head Button Modification

|

|

Adjusting the Carburetors

With the new head buttons and MKX series carbs. installed, the

engine is now at least capable of proper operation. All that

remains is the challenge of properly adjusting the carburetors.

First, you should understand that both cylinders share

both carburetors. They are not exclusive! This means there will

be considerable interaction between the carburetors during the

adjustment procedure. It is possible to have good top end power

with one carb set very rich and the other very lean. However,

the idle and mid-range will be terrible. Getting the settings

properly synchronized is the tough part. What we did was remove

the carbs. and install them individually on an Eagle .60 where

they were adjusted for similar operating characteristics. Then

they were re-installed on the 1.20 and adjusted together, one

click at a time until proper settings were achieved. Try to think

of the the carbs. as being one large carburetor rather than individual

carburetors for each cylinder.When you make an adjustment to

one, make the same adjustment to the other. Of course, it helps

when both carbs. are pre-set to about the same settings. If you

don't have an Eagle .60 on which to adjust the carbs. separately,

then pre-set the needle valves as described in our section on

MKX carburetors and start from there.

This is a procedure that requires a lot of patience, but hang

in there and you'll find that proper operation is achievable.

When properly adjusted, the 1.20

will start easily on one cylinder, then a touch of the glow clip

will fire up the other. Since the cylinders fire together, the

engine is also very smooth with little vibration, and tends to

sound more like a large single than a twin.

Propeller Note

Unlike 4-stroke or gas engines, the 1.20 is not happy swinging

large propellers. If lugged down much below 10,000 rpm it will

quickly overheat. Note the following quote from the owners

manual:

"In selecting your propeller

remember that the Fox Twin is a high speed machine designed to

run in the 11,000 to 14,000 RPM range.. ...In practice, an 11-8

is about as small as practical and a 16-4 is about as large as

practical. Leave the huge propellers for motors that are incapable

of revving up". |

|