|

The MKX series was introduced

in 1980, beginning with the flange-mount type for engines .40

size and larger. These remained compatible with earlier engines

with three sizes originally available: the MKX-A for the .40

and .45, the MKX-B for Eagle and Hawk .60's, and the MKX-C which

was intended for use with a Robart. pump. These were all built

in the same casting but had different bore sizes. Additional

carburetors were soon added to this series with bore sizes suited

to applications such as Q500, piped engines, etc.. MKX series

carburetors eventually appeared on the smaller Fox engines as

well and, finally, those strange old 2-jet carburetors faded

into history.

TN Carburetor Concept:

This second-generation carburetor

represents a departure in tradition in that the concept did not

originate with Fox. In fact, the MK-X series follows the TN (two-needle)

design practice most commonly used today, although many manufacturers

still use simple air-bleed carburetors on their economy models.

While it may not be unique in concept, the MK-X series is still

unmistakably Fox in appearance.

The TN design concept employs

only a single fuel jet, yet has two needle valves to control

high and low-speed mixture. The high-speed needle assembly is

attached to the carburetor body in the usual manner, but the

low-speed needle is attached to the throttle barrel and moves

in and out of the carburetor body in a helical fashion as the

throttle arm is moved. As the throttle is closed the low-speed

needle travels inward, along with the barrel, gradually entering

the jet and reducing the fuel flow. The fuel/air mixture is thus

metered properly throughout the entire speed range.

A point of interest is the unusually

long helical movement of the throttle barrel. This allowed greater

control over the taper of the idle needle for more precise fuel

metering. Fox even included instructions on how to modify the

taper to customize performance, but we would recommend this only

to those very experienced with model engines. The idle needles

are generally acceptable in stock form, and the average modeler

is likely to do more harm than good attempting modifications

this delicate.

MK-X Adjustment Procedure:

If the carburetor is far out

of adjustment and the engine will not run, begin by screwing

the high-speed needle all the way in, then turn it out 3 turns.

Next close the throttle barrel until only a small slit is showing,

then connect a length of tubing to the fuel nipple and blow through

it. Adjust the idle needle until air is just able to pass through

the tubing. As the throttle is opened there should be a noticeable

increase in air-flow. This should give you a ballpark setting

to begin with. Start the engine, advance to full throttle, then

adjust the high-speed needle until the engine holds a steady

2-stroke setting. Next, reduce the throttle until the engine

is at a fast idle, then, after a few seconds, advance the throttle

smoothly. The engine should quickly, and smoothly, return to

full throttle.

If there is a significant hesitation,

the idle needle requires adjustment. At this point many modelers

have trouble determining which way to go on the adjustment, rich

or lean? If you observe and listen carefully, the nature of the

of the hesitation will give you a clue. If, when the throttle

is advanced, the engine sputters and clears very slowly while

spewing lots of smoke and raw fuel out the exhaust, this is an

indication that the idle mixture is too rich, so turn the idle

needle in to lean it. If the hesitation is very short followed

by a very abrupt return to full throttle, or the engine idles

only briefly then quits, the idle mixture is too lean, so turn

the idle needle out to richen it. If you find that the engine

will idle for long periods of time but will not speed up, or

even chokes and slows when the throttle is advanced, this also

indicates a slightly lean idle mixture.

Continue to cycle the throttle

from idle to full throttle while adjusting the idle needle in

small 1/8 turn steps until you achieve a smooth transition. If

the idle needle is far out of adjustment you will find that the

small adjustment steps seem to have little effect at first. As

the needle approaches the proper setting however, it becomes

more and more sensitive until just a few degrees of adjustment

makes a significant difference. If you do not proceed slowly,

and carefully, you can easily go too far and pass right over

the optimum setting! As you approach the correct setting you

will also notice that the idle speed, from which the engine can

transition smoothly, becomes lower and lower. The best overall

carburetor performance is generally achieved when the "idle

mixture needle" is set as lean as possible without significant

hesitation. For safety, stop the engine when adjusting the idle

needle!

! Important Note

Some modelers attempt to use

the idle needle to adjust the idle "speed". This is

not correct! Once the correct idle mixture has been achieved,

as determined by good throttle transition, open or close the

"throttle barrel" as required to adjust the idle speed.

When you are happy with the idle

and transition, go back and fine-tune the high-speed needle.

Adjust for maximum speed then, richen the mixture slightly until

there is an audible decrease in rpm. Always change the needle

setting very slowly allowing the engine time to adjust to the

new mixture. When the nose of the model is held vertical, there

should be an audible increase in rpm. If the engine sags, even

slightly, the mixture is too lean! Get in the habit of performing

a nose high, full throttle check before every flight. Don't assume

all is well just because the last flight was ok. Model engines

are very sensitive to changes in temperature, humidity etc. and

may require some small adjustment of the high-speed needle as

the day progresses.

MK-X Problems and Solutions:

Poor throttle response, frequent

"flame-outs" and difficulty finding a consistent high-speed

needle setting are common complaints, however, the carburetor

is not always the main problem. Rather than the carburetor, these

problems are more often due to the design of the head button

and/or, in the case of ABC engines, a poor piston-liner fit.

Our Modifications and Projects

section offers solutions for many Fox engine problems that may

seem carburetor related, but really aren't the fault of the carburetor

at all.

The MKX series often tends to

run quite rich in the midrange, even with the low speed needle

set as lean as possible. This is due to the high fuel draw characteristics

of this series, along with inconsistent manufacture of the low-speed

needle. Most modelers will tolerate this, but if you want better

performance we suggest installing a Perry carburetor (or the

new Fox improved TN when available). You can also try the later

Fox "EZ" series carburetor, but be aware that a small

modification may be required. (Refer to the page on EZ

series carburetors).

Fuel Leakage

Leakage is a problem that may be encountered on some MKX series

carburetors. Fuel leaking from the threads of the high-speed

needle, and fuel nipple, not only makes for less consistent needle

settings, it is also sprayed back onto the engine by the propeller

blast. The oil in the fuel bakes on and, before long, the engine

becomes an unsightly black mess! Fuel leakage can be substantially

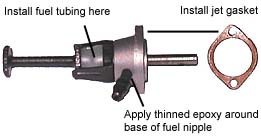

reduced by employing the modifications indicated in the picture

below:

|

Installing a short piece of fuel

tubing on the high-speed needle will stop fuel from leaking back

through the threads. Some carburetor models use a slotted nut

to retain the spring clip. This nut must be installed with the

slot facing in, or fuel may still leak past the slot. The fuel

nipple can be sealed by applying a small amount of thinned epoxy

where it enters the jet assembly. Apply with a small brush or

toothpick. Note that the idle needle does not require sealing

because the fuel is not under pressure at that point. Although

earlier carbs. did not have one, Fox

now has gaskets to provide a better seal between the jet assembly

and carburetor body. The gasket not only prevents fuel leakage,

it also prevents drawing in extra air which can upset the fuel

metering process. You can contact Fox Mfg. to obtain a gasket,

or alternately, you can carefully apply a thin layer of RTV silicone

around the edge of the jet assembly where it mates to the carburetor

body.

Inconsistent Idle due to Cam

Screw Fit and Wear

The cam screw retains the throttle

barrel in the carburetor casting and rides in slot that is milled

into the barrel. The angle of this slot determines the in-out

motion of the barrel as the throttle is opened and closed. The

problem is the excess clearance between the cam screw and slot. The cam screw retains the throttle

barrel in the carburetor casting and rides in slot that is milled

into the barrel. The angle of this slot determines the in-out

motion of the barrel as the throttle is opened and closed. The

problem is the excess clearance between the cam screw and slot.

Not only does the cam screw have some clearance in the slot even

when new, it also tends to wear rather quickly resulting in significant

in and out movement of the barrel even though the throttle arm

has not been moved. This can result in an inconsistent low-speed

mixture that is particularly annoying at lower idle speeds. You

may find that, for the same throttle setting, the idle may be

perfect one time but too lean or too rich the next. No matter

how much you fiddle with the low-speed needle the problem remains

because the position of the barrel, and thus the idle needle,

constantly varies.

There is an easy cure for this,

however, and it is the same one commonly employed by other makers

of TN type carburetors. The fix involves simply installing a

spring at the end of the throttle barrel to provide constant

tension against the cam screw. In flange-mount MKX carburetors

the barrel already has a suitable recess machined into the end

that, seemingly, was intended for this very purpose but never

employed by Fox. The spring from an inexpensive ball point pen

can be modified for this purpose. The procedure is simple: Remove

the cam screw, slip out the barrel, slip the

*pre-cut

spring over the spray bar, reinstall the barrel and cam screw.

*You'll have to cut the spring to a suitable

length. We have found that 4 or 5 turns is about right for a

typical ball point pen spring but you may have to do some experimenting

depending upon what spring you actually have. You want enough

spring to keep the barrel nicely tensioned against the cam screw,

but not so much that the throttle action becomes too heavy at

low throttle settings. A light pressure is all that is really

required. Also, if you make the spring too long you may not be

able to close the throttle barrel far enough. It may take a little

experimenting to get it just right, but it's really not a difficult

task on the flange-mount MKX carburetors.

Add a barrel tensioning spring to

make idle and transition more consistent |

For the square-neck type carburetors,

like those used on the small frame .40, the spring fix is more

difficult, although not impossible. The added difficulty is due

to the fact that the barrel on these carburetors does not have

the recess in the end, which means there is very little extra

space for a spring. To allow the throttle to close fully there

is only enough room for a couple of coils. The typical ball point

pen spring may no longer be suitable as the spring wire is often

too thick to come up with a suitable spring rate with so few

turns. We have had success using finer springs with the coils

suitably spread. Although is only possible to get tension at

low throttle settings, this is where it is required the most

anyway. Finding a source of small springs to play with will be

up to you. Of course, if you have the capability, it is also

possible to machine a recess in the end of the barrel which will

give you a lot more latitude in spring selection.

If you have questions related to

MKX series carburetors you can use our contact

form

|

|