|

OWNERS MANUAL FOR FOX 46BB ABC MOTOR FEBRUARY 1994 |

|

We are very proud of this motor and we want yours to give you the bet possible service. Please read this Owner's Manual in its entirety and follow our instructions to the best of your ability. If you have any questions not covered here, please feel free to call us at 501-646-1656. SUITABLE MODELS: This motor is suitable for radio control models calling for motor sizes from 40 thru 60. |

|

WARNING: There is always the possibility you may lose control of your model. Do not fly in any location where your model might strike people or do property damage should this occur. |

|

INSTALLATION: Your FOX motor mounts in the normal manner. If your airplane calls for a firewall mount, we recommend that it is very rigid. If your airplane is designed with a hardwood beam type mount, be sure they are well braced between the two beams, and the beams are gusseted to the firewall, and, preferably, to one another. Flimsy motor mounts will allow the engine to vibrate excessively and may damage the model and cause foaming of the fuel tank. Also, excessive vibration can cause glow plug failure. If a cowling is used, provisions should be made for both air inlet and outlet. PROPELLERS TO USE: We recommend you always use a hardwood propeller. The sizes shown are a good starting place. However, the essence of model building is experimentation. So as you feel like experimenting, try varying the pitch and diameter. |

| Large Model | Small Model | |

| Fox 46 | 11 x 6 | 10 x 6 |

| Plastic propellers are not recommended because if you should accidentally get your hand in the propeller arc while running, you will be hurt a lot worse. Wood propellers will usually break before you are seriously hurt. |

|

WARNING: Always keep clear of the propeller. It is possible for a propeller to cut off a finger or for a piece to dome off and put an eye out. |

|

FUELS TO USE: The best model airplane fuels are a mixture of methanol, pure castor oil and nitromethane to improve ignition, add power and cut down carbon deposits. It is important to use only fuel with a minimum of 17% castor oil lubricant, otherwise, your engine life will be drastically reduced. Nitro's function is to "advance the spark". To determine if you need any, or more nitro, start your engine, open the throttle wide open and set your high speed needle for maximum power, then back it out slightly. Do all this with your booster battery connected. Now remove your booster leads - if your motor slows down, more nitro is indicated. Fox Gold Star (5% Nitro) and Duke's Fuel (10% Nitro) have castor oil lubricant and should work satisfactorily. |

|

WARNING: Model airplane fuel is both flammable and extremely poisonous. Use the same safety precautions you would use with a can of gasoline or a bottle of poison. |

|

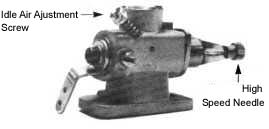

GLOW PLUGS: This motor uses the long thread glow plug. We recommend our RC-Long because it gives a more reliable performance. TO START YOUR MOTOR: Mount your motor securely on a mount that does not put a strain on the mounting legs. #4-40 screws are the size to use. The fuel supply should be so positioned that the tank centerline is not more than 1/4" below the fuel nipple. The fuel line should not be higher than the fuel level at any point. Use medium size fuel line. This motor is supplied with our new E-Z carburetor. All Fox E-Z carburetors are pre-set from the factory for easy starting. You may need to fine tune your engine to your own specifications. To set high speed needle, screw in to bottom (do not over-tighten). Then screw needle out three turns for starting point. To set idle air adjustment screw, screw it in until point of screw is midway of air inlet hole. To fine adjust idle, turn screw in to richen and out to lean. |

|

WARNING: A model airplane motor can get hot enough to cause a serious burn. Do not touch the motor after it has been running. |

|

BREAK IN: Your Fox 46 has been test run and should be bench run for a minimum of 1 hour. If a test stand is not available, motor can be broken in using a rich setting with short flights. Alternate between low speed, 1/4-1/2 throttle, and 3/4 throttle at a rich setting to allow all parts to seat properly. The idle, however, will become more reliable as the motor accumulates running time. When you install the muffler, it is important that both screws be tightened tight. Do not over torque or you will strip the threads. A bit of locktite on the threads isn't a bad idea either. WHEN THINGS DON'T GO SO WELL: Motor Won't Start

Motor Won't Keep Running with Glow Plug Heater Removed

Motor Goes Lean and Quits after Couple Minutes Running

Glow Plugs Burns Out Every Flight

IN CASE OF A CRASH DO NOT TURN THE PROP OVER YET! First - Remove from rest of model OTHERWISE, PROCEED TO DISASSEMBLE: To dis-assemble - remove head, rear cover and carburetor. Lift out the cylinder liner, next slip the con rod off the crankpin. The piston-rod-wrist pin assembly is not readily disassembled in a home shop and we recommend they be sent to us if work on these is required. Inspect all parts - discard any that appear damaged or worn. New parts can be obtained directly from the factory by calling (501) 646-1656 during business hours. When re-assembling, use care to get the oil hole in the rod facing the prop. If repairs are more than you want to handle and you desire us to rebuild it for you, mail directly to us. We will dis-assemble the motor, replace all necessary parts, test run and return the motor to you charges collect. It has not proven practical to make any sort of estimates. We will assure you, however, that our charges will never be more than 50 percent of the list price of a new motor. Note: A die cast spinner, back plate and screw are included with some models. The spinner back plate is designed to replace the thrust washer. Sometimes, the thrust washer sticks rather tightly on the taperlock. In this case, removal is accomplished by wrapping the thrust washer with two or three wraps of masking or similar tape. Then holding the motor with pliers around the tape and rapping the end of the crank with a wood block. |

|

WARNING: Never fly a control line model within 200 feet of power lines. Death by electrocution is possible if your model comes near a power line. Direct contact is not necessary. |

| Be Quiet - Don't aggravate the neighbors if you wish to continue enjoying your hobby. The muffler we supply reduces sound to an acceptable level for most rural flying fields. However, if there is any possibility that your model noise is aggravating someone, we suggest you add our Quiet Muffler. |

| PART NAME |

FOX 46BB ABC 14698 & 24698 |

| CRANKCASE |

24601 28.00 |

| CYLINDER HEAD (OR CLAMP) |

14542 12.00 |

| CYLINDER HEAD BUTTON |

14743 8.00 |

| CYLINDER LINER |

24605 SOLD AS A 60.00 |

| PISTON | |

| WRIST PIN | |

| WRIST PIN KEEPERS | |

| CONNECTING ROD | |

| CRANKSHAFT (NORMAL ROTATION) |

14608 B 25.00 |

| CRANKSHAFT (REVERSE ROTATION) |

14628 B 27.00 |

|

THRUST WASHER (THE ONE IN BACK OF PROP) |

26509 10.00 |

| THRUST WASHER TAPER LOCK |

26005 4.00 |

| REAR COVER |

14611 11.00 |

| PROP NUT (PKG. OF 2) |

13512 2.00 |

| PROP WASHER |

13513 3.00 |

| SCREW & GASKET SET |

14514 4.00 |

| REAR MAIN BEARING |

26042 20.00 |

| FRONT MAIN BEARING |

26043 12.00 |

| MUFFLER NORMALLY SUPPLIED |

90245 22.95 |

| MUFFLER - OPTIONAL TILT UP |

90246 22.95 |

| QUIET MUFFLER - OPTIONAL TILT DOWN |

90345 44.95 |

| QUIET MUFFLER - OPTIONAL TILT UP |

90346 44.95 |

| CARBURETOR - RC COMPLETE |

27050B E-Z 35.00 |

| SPINNER BACK PLATE |

24541 4.00 |

| SPINNER BODY |

24042 6.00 |

| SPINNER ATTACHING SCREW |

24043 2.00 |

PARTS LIST FOR FOX E-Z CARB |

||

|

|

||

| #27059B |

THROTTLE BARREL & CASTING (MATCHED ASSEMBLY ONLY) |

$22.00 |

| #23662 |

IDLE STOP SCREW & SPRING OR IDLE AIR ADJUSTMENT SCREW |

3.00 |

| #27064 | HIGH SPEED NEEDLE | 2.50 |

| #27065 |

SERVO ATTACHING SCREW WITH LOCK WASHER |

2.50 |

| #24066 | SERVO ARM | 3.00 |

| #24067 | FRICTION CLIP FOR NEEDLES (2) | 3.00 |

| #27070 | #6-40 KNURLED NUT | 2.50 |

| #27071 |

CARBURETOR JET WITH FUEL NIPPLE INSTALLED |

16.00 |

| #24072 | CAM SCREW | 3.00 |

| #90503 | FUEL NIPPLE | 3.00 |

| #27074 | JET MOUNTING SCREWS (2) | 2.50 |

| #24075 | MOUNTING SCREWS & GASKET | 2.50 |