|

PURPOSE

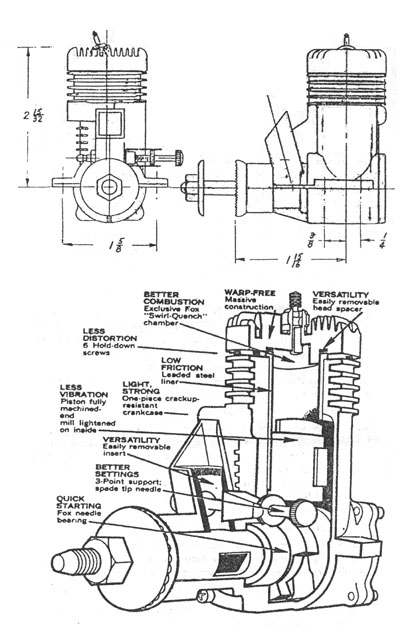

Your Fox 36X is intended primarily for free flight and control line model airplanes. It can also be used in model cars and boats.

INSTALLATION

Whatever type model your 36X is used in, the preferred mounts are hardwood beams spaced 1 9/32’ apart. The motor should be held down with four #4-40 machine screws and nuts. In the event metal mounts are used, carefully fit the mounting lugs to the mounts so no distortion of the crankcase occurs when the screws are pulled down. Do not attempt to use balsa mounts, or plywood over balsa as the motor will vibrate loose very quickly.

FUEL TANK

A separate fuel tank must be provided. The design, size and location may vary according to the type of model. Connect the tank outlet to the needle body nipple with Fox large size fuel line. We do not recommend plastic fuel line as it tends to harden and leak at the connections.

PROPELLERS

For stunt type models we recommend a 10” diameter 6” pitch wood propeller. For wing type combat models we recommend 9” diameter 7” pitch wood or nylon props. For rat race type models we recommend 8” diameter 8” pitch props.

FUEL TO USE

We recommend that your first can of fuel be Fox Superfuel. With a little running your Fox 36X will become looser and can produce more power on Missile Mist. For contest events where maximum power is desired you can use Fox Blast.

GLOW PLUGS TO USE

Ignition occurs automatically when the piston brings the fuel mixture up on compression and it is subjected to a red hot platinum coil. The platinum coil is extremely fragile and will often burn out or be broken by particles of dust that go through the motor. It is impractical to guarantee these coils and you should consider replacement of the glow plug occasionally to be a standard part of your operating expense. Use long thread plugs only.

PROCEDURE FOR STARTING MOTOR

- Set the model level, turn prop clockwise looking at front on motor until the piston is half way up. Fill tank until fuel runs out of the overflow. Remove needle valve and put back in one full turn.

- Turn propeller so exhaust port is open and insert five drops of fuel. Crank prop two or three times.

- Connect one battery lead to the centerpiece of the glow plug and the other to any convenient place on the motor.

- Start cranking counterclockwise with a short, snappy action. The motor should start running in a slow four cycle. Screw the needle valve in until the motor runs smoothly and then remove the battery leads.

If the motor fires but does not run, it is getting too much or too little fuel. Experiment with the needle valve and amount of prime accordingly. If the motor will not fire, in all likelihood your battery is dead or the glow plug has failed. Replace as required.

NEEDLE VALVE ADJUSTMENT

A model airplane motor, unlike an automobile motor, has no throttle. Speed is reduced by giving the motor too much fuel. A motor with too much fuel will run slower and miss every other revolution. This is called “4-cycling”. It is much easier on the motor to run in this condition than it is to run with too little fuel. The needle valve should be adjusted to the richest position which will give you sufficient power for the flight and still keep running.

DIS-ASSEMBLY PROCEDURE

An inexperienced person will often strip, burr, warp or otherwise, damage delicate parts, and this is the reason we do not recommend dis-assembly. However, if caution and the right tools are used you can dis-assemble and re-assemble the motor with no harm except to the gaskets which seldom seal properly the second time. This is the procedure:

- Remove the glow plug, the six head screws and the four rear cover screws. A No. 1 Philips screw driver is the size to use.

- Lift off head and rear cover. Lift out the cylinder liner. NO PLIERS!

- Turn crank so piston is down. With pointed-nose pliers pull the connecting rod back and off the crankpin.

- The piston assembly and crank may now be removed. The needle bearings are press-fitted in place with special tools and cannot be removed easily.

TO RE-ASSEMBLE

Reverse this procedure. Replace screws and gaskets. For best results no parts should be forced. Piston baffle must be on bypass side. Before replacing plug, see if motor turns over freely. If not, loosen screws, shift parts slightly and try again.

TO INSTALL IN A STUNT MODEL

Your 36X will give a more even run and smooth 2 cycle - 4 cycle transition if you will remove the head and install 3 extra head gaskets. The fuel tank should be 1” deep and setting on the motor mounts directly in back of the firewall. Filler and vents should be bent forward to receive air ram. Fox Superfuel will give the steadiest run.

TO INSTALL IN A COMBAT OR RAT RACE MODEL

Take care to make the motor mount section sturdy. Vibration from a flimsy front end will foam the fuel and give a lean run. Try to mount the tank directly in back of the needle valve, or slightly inboard if you have any choice. With a tank located mostly outboard you have a rich on the ground – lean in the air situation. For maximum performance you will want to remove the carburetor restrictor and run pressure. A pen bladder requires no motor alterations, but to run pressure on a metal tank you should install a pressure fitting or replace the rear cover with one already fitted. Your Fox 36X immediately vaporizes fuel in the case when hot. This floods the motor causing most hot re-start complaints. You will have no hot re-start problem if you keep all fuel out of the intake during refueling. Re-start on ever so small exhaust prime. You will normally use Missile Mist or Blast fuel. Blast costs more – gives more power, but is less tolerant to fuel vibrations.

TO INSTALL IN CARS OR BOATS

The fuel tank requirements are the same as for a stunt model. Although cooling in these installations is not what we would like, 36X motors have operated for many hours with no failures. We suggest using only mild fuel however.

IF YOU WANT TO HOP UP YOUR FOX 36X

All efforts to increase power output thru porting changes have been to no avail. Minor gains can sometimes be made by polishing wearing surfaces and eliminating all binds. Power increases can be obtained by increasing the compression ratio. However, the needle valve setting tends to become more critical.

IN CASE OF A CRACK-UP

From time to time you will undoubtedly have some crash landings. When this happens flush all exterior dirt off with fuel or solvent before attempting to turn over. If motor shows any sign of binding do not try to start, but dis-assemble, clean and replace any bent or broken parts.

IF YOU DESIRE A FACTORY REPAIR JOB

Package your motor and mail it to us with a letter describing any problems you may have with it. All motors we receive are put thru the following process:

- Motors are dis-assembled, washed and parts inspected.

- Motors are re-assembled, replacing screws and gaskets, and any other worn or damaged parts.

- Motors are test run.

- Motors are packaged and returned C.O.D. All motors repaired are guaranteed to run like new.

Charge for this service depends upon condition of your motor. In no event will it be more than $7.00. We accept motors only on the condition that we are authorized to make whatever repairs are necessary. Send all engine parts, either whole or dis-assembled.

NO ADVANCE ESTIMATES CAN BE GIVEN. No discounts can be allowed dealers. Please mail the motor yourself to reduce the possibility of any misunderstanding.

Enclose or attach any correspondence, and show your name and address plainly (Printing is best for Name and Address.)

|